Food Mixing Chillers

Many food process companies have wasted water for years by cooling their processing food by incoming city water lines. Ever since the introduction of refrigeration water chillers into the food industry in addition to the evolution of anti-freeze in a food-grade usable form called Propylene glycol, food processing has gotten easier than ever before. Many applications require a food mix to be heated up to a warm temperature and then brought back down quickly to be handled by employees and packaged. Jacketed tanks are frequently used in food applications. Additionally, hydrocooling systems are frequently used in food applications where food is washed with 35-45degF water to maintain cleanliness and freshness.

Some Common Food Applications:

· Pre Cooling of Fruits,Vegetables,Grapes Lemons,pomegrantes,Mangos etc.

· High Humidity Cold Storage for Fruits & Vegetables.

· Large Cold Storages for Agricultural Products such as Potato,Chilly,Dry Fruits etc.

· Blast Freezers & deep Freezers for Foreign Foods Processing & Preservation.

· Chilling Plant For food Processing

· Prefab Cold Room out of PUF Panels.

· Bakery Process Cooling

· Batch Cooling with 34degF Water for Mixing Ingredients

· Brewery Process Cooling

· Winery Process Cooling

· Drinking Fountain Cooling

· Fruit and Vegetable Washing

· Ice Machine Pre-Cooling

Packaged Chillers Non-expandable (integrated pump tank) 1.5Ton – 20Ton Single / Dual Circuits Single / Dual Pumps |

SAE Series Modular Chillers Expandable (pump & tank on separate skid) 1.5Ton – 200Ton Single / Dual Circuits |

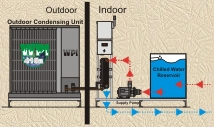

SAR Series Split Chillers Expandable (Outdoor Condensing Unit) (pump, tank, evaporator on indoor skid) 1.5Ton – 200Ton Single / Dual Circuits |